Shrimp School

Aquaculture industries are popping up in cities and rural areas across Wisconsin, but Spring Valley Aquaculture is the first to be housed in an old school.

December 14, 2016

WASAL WPI Shrimp School illustration crop

With the beginning of fall come memories of schooldays: whiffs of freshly sharpened pencils, the ringing of assembly bells, and flurries of young people running through the halls. At one particular old school in Newton these familiar smells and sounds have been replaced by the scent of brine and the thrum of the water pumps powering a new shrimp farm called Spring Valley Aquaculture.

While aquaculture has been used for thousands of years to grow and harvest fish and plants alike, it has become a burgeoning commercial enterprise in the past fifty or so years. Today aquaculture industries are popping up in cities and rural areas across Wisconsin, but Spring Valley Aquaculture is the first to be housed in an old school.

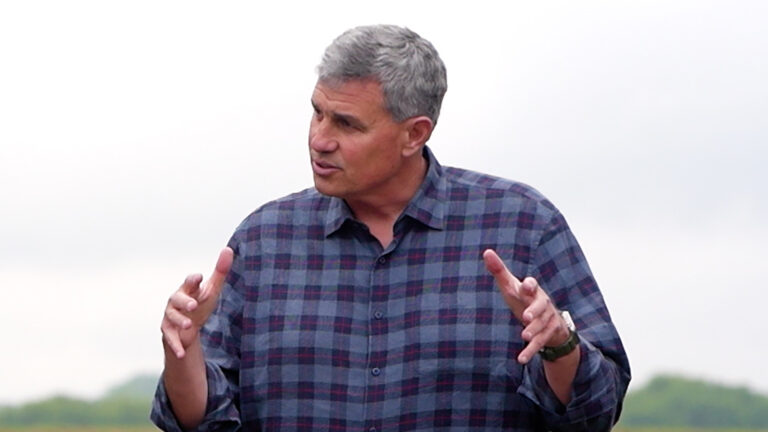

Russ Albert II, his daughter Stephanie, and girlfriend Connie Jedrzejewski began raising Pacific white shrimp (Litopenaeus vannamei) in Meeme Elementary Charter School back in May of 2016. The school’s gymnasium is now home to eleven nine-by-eighteen-foot saltwater pools that, along with some related water management equipment, daily circulate roughly 44,000 gallons of water. Incubation of the baby shrimp happens in a series of five aerated nursery pools in an adjacent room. Both spaces have been heavily insulated with spray foam in order to maintain a consistent temperature of 93 degrees Fahrenheit — perfect for raising Pacific white shrimp.

Native to the eastern Pacific Ocean, Pacific white shrimp can be found in most American stores and restaurants. According to Consumer Reports, almost 94 percent of the shrimp Americans consume come from abroad, particularly from Asia and Latin America. About half of this shrimp is raised in outdoor ponds, manmade streams, or tanks. However, the conditions in which these shrimp are raised vary widely, and the same Consumer Reports study found unacceptable levels of bacteria in 60 percent of frozen, farm-raised shrimp from abroad. Additionally, these types of shrimp farms can be harmful to the environment by polluting nearby bodies of water with chemicals and antibiotics, wasting huge amounts of water, and potentially damaging the shrimp’s natural breeding habitats, such as red mangrove forests.

Chris Hartleb, co-director of the Northern Aquaculture Demonstration Facility at UW-Stevens Point, notes that aquaculture can be done in a sustainable way that minimizes environmental impact. Spring Valley Aquaculture, for instance, operates what is called a Recirculating Aquaculture System (RAS). This is touted as the most sustainable way to produce shrimp, or engage in any form of aquaculture because of the way it limits water waste.

“In an RAS, the water is in a closed system that recirculates and the only water replacement that you would have is through any water evaporation that would occur. And it’s usually fairly minor. They may only replace 1 percent to 3 percent of the water each day because of evaporation. It is a very low consumer of our water resource,” Hartleb explains, adding that “there’s a lot more shrimp in that tank than you would find in the same square footage in the ocean, so you’re producing quite a lot of shrimp or protein in a very small footprint.”

According to Hartleb, the world’s seafood catch has stagnated at around one hundred million metric tons per year, despite new technology and the drive to reap more fish. This is why so many people are turning to aquaculture to meet consumer demand.

Shrimp farming in Wisconsin, however, is a relatively novel enterprise. Hartleb says there are over 2,500 registered aquaculture farms in the state, but only five of these are shrimp farms. The rest are mostly producing trout or other lake fish for consumption.

As the most-frequently consumed seafood product in the United States, shrimp are very profitable for farmers. Stephanie, Russ, and Connie got the idea to raise shrimp from Russ’s father, who thought that the business could yield a sizeable profit and perhaps revitalize the small town of Newton, which is located just nine miles south of Manitowoc. They found a good fit for their operation when the Kiel school board voted to close Meeme Elementary due to declining enrollment in 2014. The school remained vacant until Russ bought the fourteen-acre property for $275,000 in 2015.

Stephanie, Russ, and Connie are quick to note that their ambitions in some ways outpaced their knowledge about what exactly it takes to operate a thriving shrimp farm, as none of them have specific experience in the area. Stephanie is a recent biology graduate of UW-Oshkosh, Russ owns a hydro excavation company, and Connie is currently a teacher with a background as a naturalist in the Milwaukee Public Schools Outdoor Education Department. Yet the three believe that they have a unique opportunity to breathe new life into the old school and, in words of Russ Senior, “put Newton back on the map.”

The farming process begins when Spring Valley Aquaculture receives the baby shrimp in the post-larval stage, which are shipped overnight from Shrimp Improvement Systems, a leading provider of shrimp varieties that have been selectively bred for desirable traits, such as resistance to disease-causing pathogens.

When the baby shrimp arrive “they’re smaller than a grain of rice with these little eyeballs that stare at you,” Connie says. But, like kindergartners moving from grade to grade, the shrimp transform dramatically over time.

To ensure a high survival rate, the baby shrimp are first placed in an initial nursery pool for roughly one month where they become acclimated to the conditions they will face in the grow out pools. They are then divided by size into different grow out pools where they continue to mature. The shrimp are fed commercially-produced pellets that contain all the essential nutrients for both healthy shrimp and safe human consumption.

“[The shrimp] get fed four times a day. Usually at 7:00 am, 12:00 noon, 5:00 pm, and 10:00 pm. And then at some point during the day we test with a probe for dissolved oxygen, temperature, pH, salinity, and we do a test for ammonia and nitrate,” describes Stephanie.

Over time, the grow out pools accumulate bacteria that will both enhance levels of ammonia and nitrate in the pool as well as act as supplemental feed for the shrimp. The shrimp progress from juvenile to sub-adults and finally to adults, ready to be sold — fully intact with shells, heads, and tails — to local consumers and restaurants straight from the doorstep of the old school.

“We’ll fish them out of the pool in a Ziplock baggie with ice and out the door you go. You’ll get the freshest possible thing you can get, still flipping around on ice when you walk out of here,” Connie says.

Russ, Stephanie, and Connie aim to harvest and sell the first batch of shrimp to their neighbors and the general public in November or December 2016.

“Like any new business, there is a learning curve. Some of the people in the business say you haven’t learned anything until you’ve killed off a million [shrimp]. We haven’t gotten there yet … but you are constantly learning and researching and looking for the best practice,” Connie says.

Today there are about 90,000 shrimp inside the Spring Valley Aquaculture building. In the quest to make a more sustainable operation and healthier shrimp, Russ, Stephanie, and Connie are currently attempting to introduce natural vegetation such as red mangroves and Chaetomorpha seaweed into the pools as a non-artificial way to maintain the water’s nitrate and nitrite levels.

Connie says that the Spring Valley Aquaculture team is looking forward to cultivating deeper connections with the community. They say they hope to keep the school’s library, still with shelves of books left behind from the closing, open for public meetings or summer tutoring programs, host field trips for local school kids to visit the farm, and hire a student intern to encourage an interest in aquaculture. Since Spring Valley Aquaculture is still in the midst of its first shrimp harvest, though, these aspirations are, for the moment, second in line to nailing down exactly what it takes to run a successful shrimp farm.

Editor’s note: This article was originally published in the Fall 2016 issue of Wisconsin People & Ideas, and is copyrighted to the Wisconsin Academy of Sciences, Arts & Letters.

Passport

Passport

Follow Us