Frederica Freyberg:

In other news, supply chain dysfunction, which began with the COVID-19 pandemic and got worse with the Russian invasion of Ukraine continues to challenge Wisconsin manufacturers. Unpredictable demand, material shortages and disappointing crop harvests have all played a role in sending prices soaring. “Here & Now” reporter Will Cushman has the story of one Wisconsin business in Dane County.

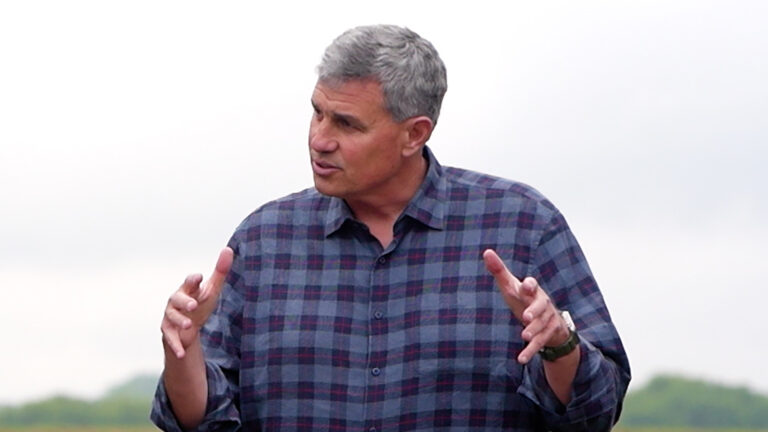

Isaac Showaki:

The pandemic has been — what’s the right word, like very interesting and very volatile in our business.

Will Cushman:

When Isaac Showaki opened Octopi Brewing in the Madison suburb of Waunakee in 2014, he expected some challenges. He never imagined the dizzying business disruptions that accompany a long, deadly pandemic. The trouble began in early 2020.

Isaac Showaki:

When it hit in March, all of a sudden over 48 hours, about 60% of our orders got canceled.

Will Cushman:

Octopis core business is producing drinks on contracts. Primarily for brands that sell in supermarkets. After only a couple weeks of lockdowns, it became clear that demand for supermarket products was about to go into overdrive.

Isaac Showaki:

Orders started coming in fast and furious and we got really busy really fast because the demand for just consumer product goods, especially in the off premise and supermarket chains went through the roof. So 2020 was a very scary time, but then it was, like, a really good time for us.

Will Cushman:

Those good times relied on a global supply chain that had never been subjected to a stress test like a multiyear pandemic. Octopis supply chain faired relatively well in 2020.

Isaac Showaki:

At that point I didn’t think there were any issues keeping up with demand, because anything we needed, we were getting.

Will Cushman:

But that began to change.

Isaac Showaki:

I would say end of 2020, beginning of 2021, we started seeing the rumblings.

Will Cushman:

First, tariffs on aluminum sent the price of cans higher.

Isaac Showaki:

Then we started hearing of demand issues, right? Like we can’t supply all the items, all the cans that you need. Then it was glass.

Will Cushman:

By the end of 2021, supply chain snags snowballed into a global mess. A fall 2021 survey of Wisconsin manufacturers found the two most pressing issues they faced were unreliable supply and skyrocketing prices of materials. Showaki says this year is shaping up to be even more challenging.

Isaac Showaki:

It was just not one thing. It was everything started getting affected. Every single piece in the supply chain from raw materials to packaging materials, we started having issues like not being able to get the product or significant price increases that are unprecedented, you know, like, I think the smallest price increase was about 15%, but on average, it’s been between 20 and 25% over the last six months.

Jake Dean:

Weve built a supply chain system that included factories, that includes distribution centers, that includes transportation methods, and all that stuff. We’ve built that to handle a certain capacity that we thought was coming at us.

Will Cushman:

Jake Dean studies how supply chains work or in the last couple years, more like how they come apart.

Jake Dean:

It’s been a really fun job to be in over the last couple years as an observer of supply chain rather than as a practitioner of supply chain.

Will Cushman:

Supply chain practitioners have faced a whirlwind of challenges: material shortages, worker shortages and rising labor costs, a global shipping industry in disarray. Perhaps the biggest challenge has been unpredictable and highly variable demand.

Jake Dean:

We’ve invested a lot in supply chains over the years, figuring out where demand is, and what we need to satisfy and those sorts of things. But part of those things being accurate requires some brain power and computational power on, to a certain extent, past behavior. And when you have no past behavior to model, you don’t know what happens when the world economy goes screwy.

Joel Yaeger:

Adaptability overall has been kind of the theme of COVID.

Will Cushman:

Joel Yaeger is Octopis CFO. Over the last couple years, a big part of his job has been adapting the growing business to weather supply chain problems. This means finding as many backup suppliers as possible for key materials. It’s not only the pandemic and tariffs disrupting Octopis supply chain. Malt is a key brewing ingredient derived from barley, and the outbreak of war in Europe has affected its supply.

Joel Yaeger:

Ukraine is a huge producer of malt. Not so much of what goes into beer but even for livestock.

Will Cushman:

The war is compounding an already difficult situation.

Isaac Showaki:

They had a horrible crop year last year, so about 25, 30% of the crop was lost so then there was a small supply of malt and then the price went up 25%. Unprecedented. We used to get 2, 3% price changes.

Will Cushman:

The pandemic economy has also scrambled Octopis expansion plans. In April, a space for a massive new canning line stood empty. The problem, a semiconductor shortage meant the line’s high-tech controls weren’t ready.

Jake Dean:

It might be two parts that are waiting to finish the machine, but without those two parts, you can’t make the machine.

Will Cushman:

Octopis supplier said the canning line should be ready by early fall. That’s around when Showaki expects consumers will feel the full weight of price increases his business has encountered.

Isaac Showaki:

We’re just giving our price increases to our clients, which is going to take a few months to get to the retailer which might take a few months to go to the end consumer.

Will Cushman:

These price increases on everything are likely to continue fueling inflation. This spring, the Federal Reserve has started ratcheting up interest rates in a bid to tackle soaring prices by cooling consumer demand.

Jake Dean:

As long as consumer behavior is unpredictable, supply chains are going to be unpredictable.

Will Cushman:

While there are signs demand may be normalizing, it’s no sure bet. Over the near term, global turmoil will likely continue to keep consumers and manufacturers on their toes. Reporting from Waunakee, Im Will Cushman for “Here & Now.”

Search Episodes

Donate to sign up. Activate and sign in to Passport. It's that easy to help PBS Wisconsin serve your community through media that educates, inspires, and entertains.

Make your membership gift today

Only for new users: Activate Passport using your code or email address

Already a member?

Look up my account

Need some help? Go to FAQ or visit PBS Passport Help

Need help accessing PBS Wisconsin anywhere?

Online Access | Platform & Device Access | Cable or Satellite Access | Over-The-Air Access

Visit Access Guide

Need help accessing PBS Wisconsin anywhere?

Visit Our

Live TV Access Guide

Online AccessPlatform & Device Access

Cable or Satellite Access

Over-The-Air Access

Visit Access Guide

Passport

Passport

Follow Us